Frechettes’ La Broquerie silo used to be largest in Manitoba

Advertisement

Hey there, time traveller!

This article was published 22/11/2022 (971 days ago), so information in it may no longer be current.

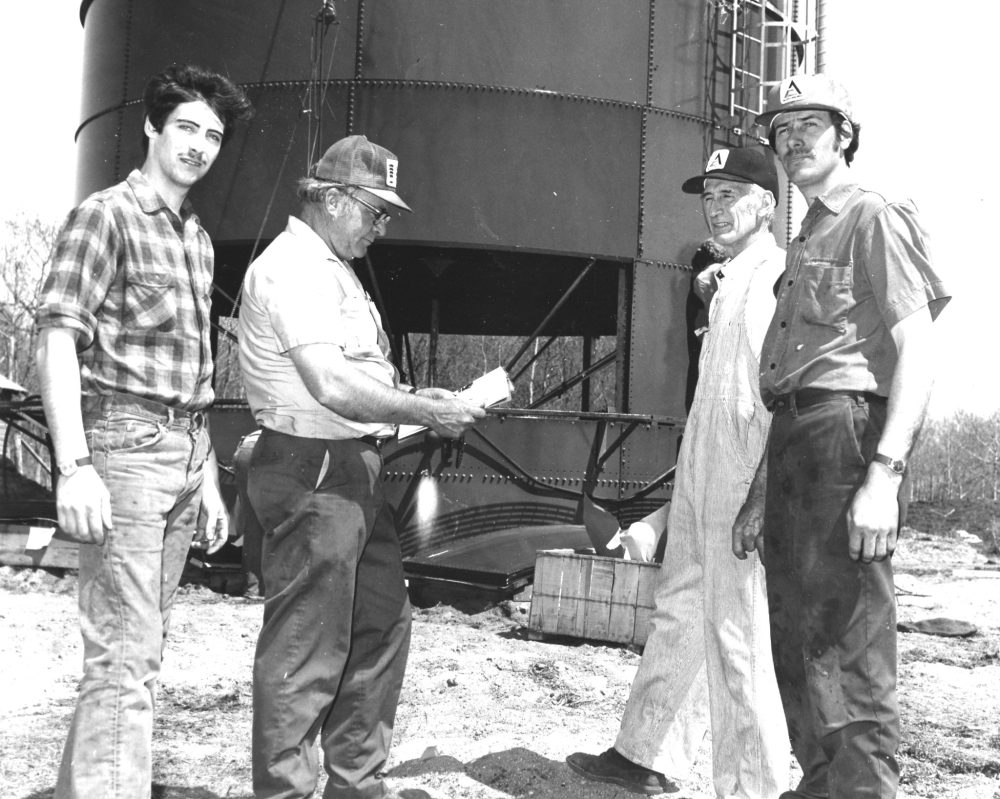

The glass-lined silo constructed at a dairy farm near La Broquerie in 1975 was the largest to be built in Manitoba at the time.

It took 300 man-hours to erect, the 90-foot high structure with a capacity of 700 tons of wet haylage, and was designed to allow Armand Frechette and his sons to increase their dairy herd, while cutting down on labour.

The first 90-foot Harvestore to be built in Manitoba reached 65 feet in height within a week and construction foreman Lloyd Verley and his crew finished in another day.

Once the silo reached 50 feet, all work would have to be stopped if winds reached over 20 miles per hour, but weather co-operated and the towering structure was completed by mid-May.

To take advantage of good weather, the crew often worked as many as 15 hours per day. But the foreman said his men didn’t really complain much, because they were mostly American college students and could use the overtime to help pay for their education.

One of the men working on the La Broquerie Harvestore was studying to be a dentist and another had one university degree and was working towards another.

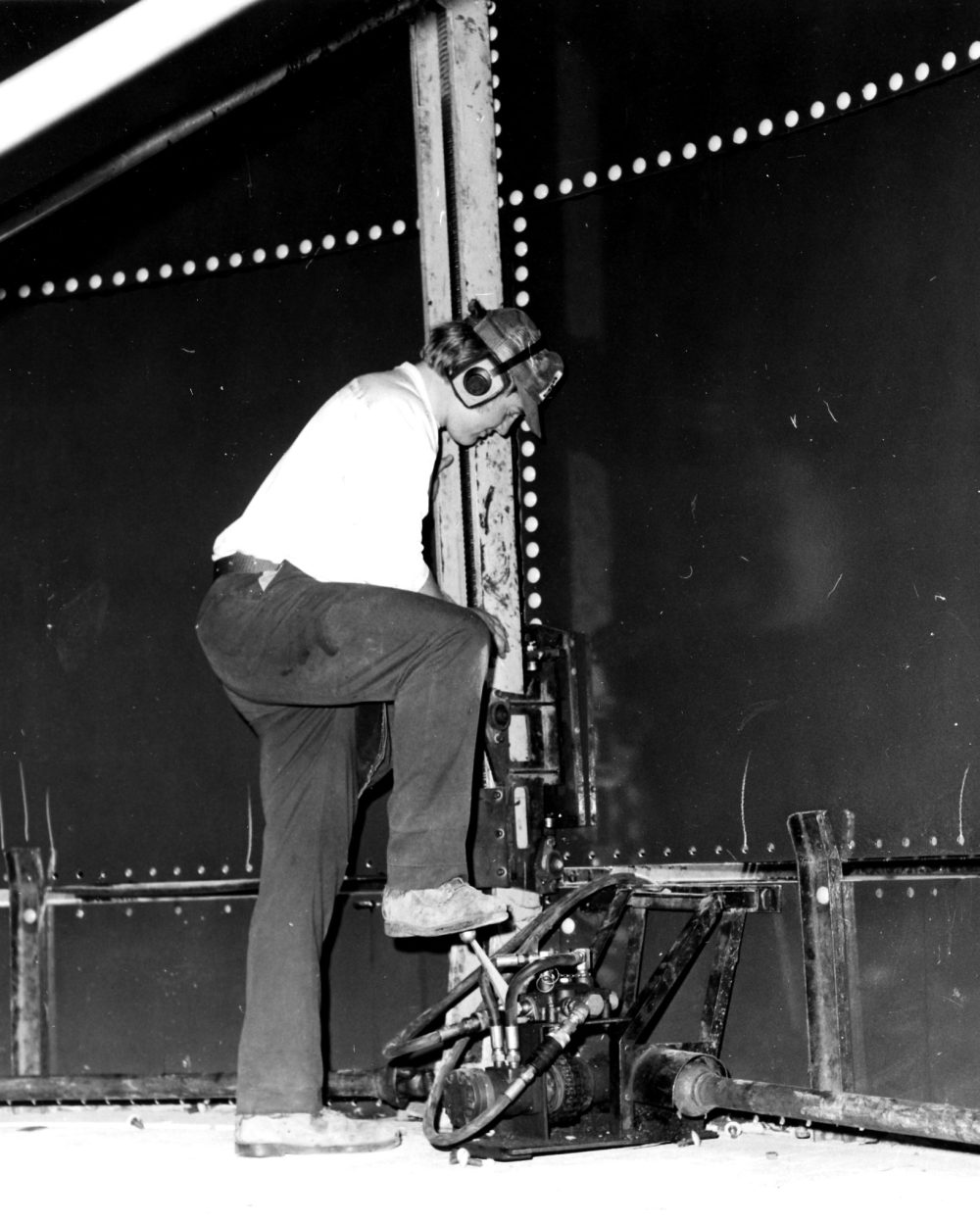

Amazingly enough, the silo was built on the ground. The top of the silo, complete with air breather bags designed to control oxygen, was installed first. Then nine hydraulic jacks were utilized to raise the structure to allow the next row of glass plated steel panels to be bolted into place.

As soon as the first row of sheets was installed, the structure was again elevated by the jacks. The Harvestore was literally built from the top down, each row of steel plates moving it up another five feet.

Once the structure was completed, the foreman checked for leaks and the province’s largest glass-lined silo was ready for operation.

For the Frechettes, the construction on their farm automated their feeding system and left them that much more time to get the rest of their 2,000 acres into production.

At the time, Leo Frechette explained they had about half their farm under hay, pasture and grain, but there was a great deal of bush left to be cleared.

They were also planning an expansion of their free stall barn and were going to increase the size of their herd.

With the controlled environment the new silo would provide for feed, the La Broquerie dairy producer said they might try adding corn for feed in 1976.

Before the silo was constructed, the farm was equipped with bunker silos, and though the Harvestore was more expensive than a more conventional concrete silo, Frechette said they chose the glass-lined structure to ensure the very best feed possible for their cattle.

Frechette said he thought he could have a complete year’s supply of feed stored in the 90-foot silo if he refilled it with the second hay crop. In that way, he would not have to pasture his cattle, leaving more of the farm free for either hay or grain crops.

The Frechette Dairy, in 1975, was a four-man operation, with Armand Frechette joined by his sons Leo, David, and Ernest, who was still attending school at the time.

The Frechettes were shipping about 75,000 pounds of milk per month, but expected to increase to about 100,000 once an extension to the barn was completed and 25 cows were added to their herd.

While the Frechettes were the first to install the 90-foot Harvestore silo at their La Broquerie dairy farm it didn’t take long for others to follow suit.

Two years later, a drive through the area north of Steinbach revealed the popularity of silos, for at least one of the distinctive metal structures was always visible against the horizon.

Harvestore salesman Bob Brandt indicated that by 1977 more than 80 units had been constructed east of the Red River.

Despite their relatively steep price tag, running up to $68,000, and a reputation of being the “Cadillac” of silos, Brandt told The Carillon in 1977 that the silo was not seen as a status symbol, but rather, an investment for livestock farmers.

When one farmer put up a Harvestore, others soon followed, because they could see firsthand the efficiency the silo provides.

One area milk producer said switching to high moisture haylage had increased the productivity of his herd by 1,350 pounds per cow per year, with no drop in butterfat.

Today, the glass-lined slurry-store has become just about as popular for manure storage as the glass-line silo was for feed storage back then.