COLUMN: Carillon Flashback – October 13, 1966: Super-hard sidewalk blocks new at Barkman Concrete

Advertisement

Hey there, time traveller!

This article was published 31/01/2024 (556 days ago), so information in it may no longer be current.

A new concrete press, one of only six in Canada, went into operation at the Barkman Concrete plant in Steinbach this month. Built by Fielding Machine in Gloucester, England, the hydraulic press produces a super-hard concrete, which, is expected to revolutionize the whole concrete industry in the next few years.

By applying a pressure of 1,500 pounds per square inch on cement in a mould, the Fielding hydraulic press produces a block which compares favorably with the hardest granite. Chemists who have studied the products produced by the new hydraulic press cannot see any reason why they should not last for 1,000 years.

While the new concrete block may not look much different from the old poured concrete to the unpracticed eye, it is in fact so different that it is almost another substance. The difference lies in its density. The 400 tons of pressure applied by the surface of the press to the concrete in the mould, compresses the cement so firmly that all the water is literally squeezed out of the concrete, leaving no pores at all.

In the case of the old type of concrete, tiny quantities of water collected inside the pores of the cement. In cold weather, this water froze, and expanded, breaking down the inner structure of the cement block in the sidewalk. Since the new concrete has no pores, it should not suffer from deterioration of any kind, despite freezing temperatures.

For the time being, Barkman Concrete will use the new machine chiefly for making cement sidewalk and patio blocks. But the company sees a tremendous use for the new machine in the manufacture of street curbing for use on town and city streets.

Not only would this type of curbing be impervious to the usual eroding effects of the elements, but it would withstand the kind of physical punishment which is now responsible for a lot of damage to curbs and sidewalks.

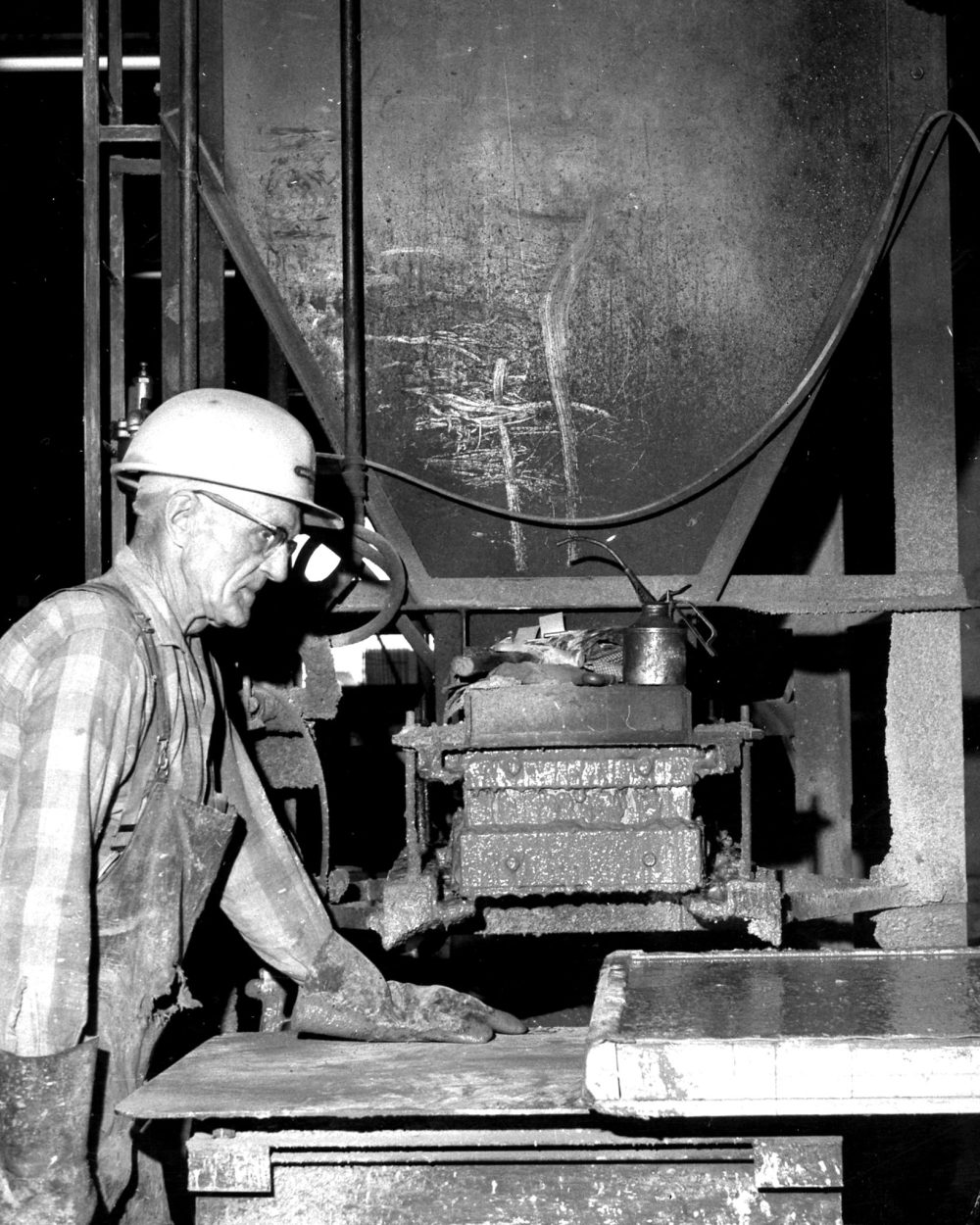

The press itself looks very much as you would expect such a machine to look – a tall mass of metal beams, tubes and blocks, interlaced with the hydraulic pipes and cylinders, which will provide its power. The machine weighs 33,000 lbs. and fully installed, costs about $45,000.

Until this year, there were only two hydraulic concrete presses in Canada. One of those was in Toronto, where its owners have already sold large quantities of sidewalk blocks to the City of Toronto.

Barkman Concrete’s manager Peter Barkman says that the new concrete products compare very favorably in price with the conventional type of poured concrete.

Barkman Concrete Products had its beginnings in the production of concrete septic tanks back in 1950, when it was still known as Barkman Hardware. Since then, the company has added to its product line sidewalk and patio blocks, unit steps and railings, parking lot curbs and floor slats for hog barn floors.

At present, Barkman Concrete Products employs about 75 people year around. The number increases during the busy summer season. Thirty men work in the concrete factory, and about 15 in the plumbing and heating department in Steinbach, while another 30 work in the Winnipeg distribution centre.